Abingdon Reservoir: how much will it cost?

The proposed reservoir will be Oxfordshire’s most expensive infrastructure project ever. In the last part of his personal look at the project, Andy Cooke asks if costs will be kept under control.

For a moment, let’s ignore issues raised in the last two articles and assume it is decided that we go for SESRO. Can we simply answer the questions of “What will it cost?” and “How long will it take?”

If anyone thinks it’d come in at £2 billion and 10 years, then get in contact; I’ve got a friend who can get a good deal on London Bridge. I could point at HS2, which was costed at £15.8-£17.2 billion at a similar phase. I believe it’s now coming in over £100 billion and still rising.

When it comes to building the biggest ever bunded reservoir, we don’t have much recent relevant experience in this country. As we saw last time, it’s over 30 years since a big reservoir was built (and that one had its dam collapse while being constructed, which isn’t encouraging). Getting it built at all will be challenging.

Root and branch review

Thames Water have been repeatedly showing pretty pictures of the embankment with trees and other vegetation carpeting it, making it blend in and look much nicer. This isn’t just an inexperienced artist getting imaginative – their Technical Brochure makes it clear that they intend to have: “hedgerows, woodland… to make the earthworks appear more natural and to integrate them into the surrounding landscape” (Thames Water SESRO Technical Brochure, page 46).

The problem is that experienced dam engineers know that you should never have trees on a dam embankment. Their roots create leakage paths, for a start. “Even one tree on any size dam is cause for concern” according to the US FEMA. The UK Institute of Civil Engineers also advises against trees (and shrubs, roads, and incised paths) (‘Floods and Reservoir Safety’, 4th edition, pp 35-36, Institution of Civil Engineers, 2015).

Yet in every outreach event I’ve been to by Thames Water, they’ve had trees and hedgerows all over the embankments, which smacks of PR rather than engineering. I’m looking at the ‘SESRO Spring 2025 Project Update’ from Thames Water as I speak. It’s still got trees everywhere.

How much?

It’s difficult enough to come up with reliable cost and time estimates for small projects, or for larger ones that you do frequently. For unparalleled megaprojects when you’ve not built big dams in your country for a generation…

We’ve repeatedly heard from Thames Water that SESRO would cost £2bn – a nice round figure – and that it would take 9-10 years to build. (Plus at least two years to fill, remember, assuming perfect conditions in the Thames.)

It’s always best to look around at other, similar projects. There aren’t any of this size, of course, but there are two bunded reservoirs of a third of the size being planned to be built in England, and they’re a little further down the track. It’s still early days, but the budgets for the Fens Reservoir and the Lincolnshire Reservoir (both 50 billion litres each, a third of SESRO) have expanded to £3.3bn and £3.6bn respectively… so far. On current draft forecasts, each will take at least as long to build as SESRO.

How much are you willing to believe that £2bn estimate for the far larger and more complex SESRO? What will the price tag look like when they’ve finally got round to designing it (and hopefully removed those trees)? Already, Thames Water are overrunning the schedule for their Clay Compaction Trial (which involves constructing a 3m-high clay embankment for a few dozen metres).

Over in the ignored corner, a Severn–Thames Transfer comes in at an estimated £1.5bn, according to Ofwat’s estimates, and that estimate seems more believable. We lay large water pipelines all the time: there’s an entire network in construction in East Anglia, which will convey 15m-55m litres of water per day across 350km of transfer grid, of which 170km is in the ground already. We have plenty of recent relevant expertise. That pipeline in Anglia will end up costing £0.5bn, and be complete in 2 or 3 more years. Although STT is scaled for 300m-500m litres per day, it’s much shorter than that, so that £1.5 billion estimate passes the sniff test.

In terms of capacity of water provided SESRO should give “up to 270m litres per day” (until it runs out, of course). Capacity-wise, then, STT beats SESRO hands down, as well as being faster to build and cheaper by far.

All these billions of pounds? That money comes from you and me, remember. Straight onto our water bills.

Risky business: the Iron Law

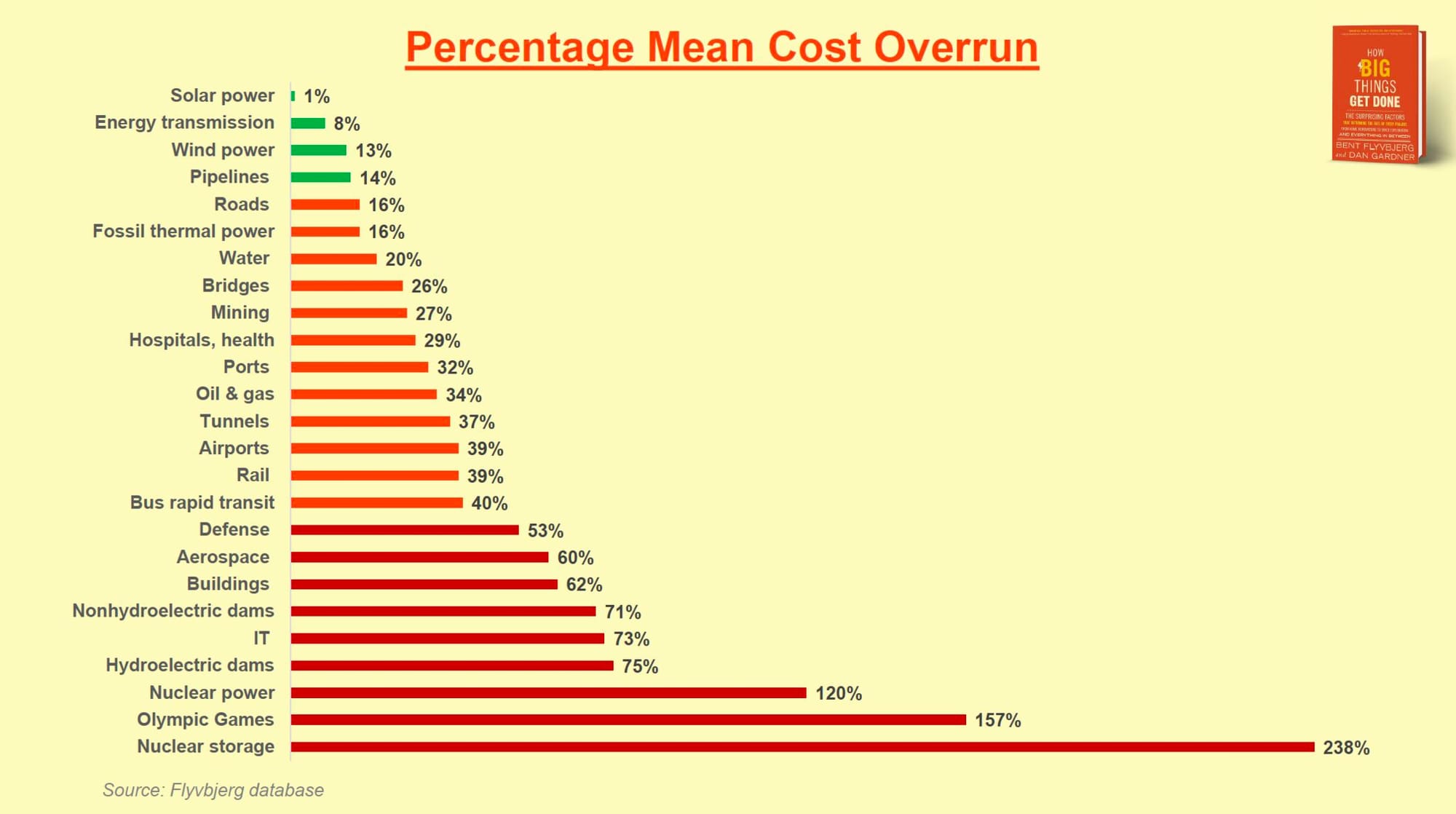

(From research by Professor Bent Flyvbjerg – the average cost overrun of types of megaprojects. SESRO is in the category of “nonhydroelectric dams”, STT is in the category of “pipelines”.)

Am I just being biased in my view that SESRO’s budget is implausible and its timeline likely to be blown past? It turns out that there’s a lot of proper research about exactly this sort of thing, and our instincts here are pretty much spot on.

I’ve used the word “megaproject” for this. That’s a word with a specific meaning and definition, and I’m using it advisedly. A megaproject is in the billions-of-pounds budget range with significant complexity. Megaprojects are in their own league of budget and timeline risk.

A professor at Oxford University, Bent Flyvbjerg, has literally written the book on megaproject risk. As well as advising Governments in multiple countries (successfully), he coined the Iron Law of Megaprojects:

“Over budget, over time, under-benefits, over and over again.”

It can be frustrating when you see the original estimates and claims on megaproject budgets and timelines seeming to get swallowed whole by journalists, politicians, commentators, and the like. Yet the seemingly inevitable huge overruns, delays, difficulties, and lack of benefits always appear to come as a (newsworthy) surprise. Every time.

You should, though, be able to think of exceptions to this Iron Law. These exceptions are very valuable at telling us what are likely to fall foul of it and which have more chance of escaping it.

Flyvbjerg went through all types of megaprojects around the world, systematically and by type. He found that projects like solar farms, wind farms, roads, electricity transmission, and pipelines have the lowest risk of being caught by the Iron Law. Or, to put it another way, they had the best chances of finding a way past it; and when they did go over budget and over time, their overspends and delays were usually noticeably lower than those for other types of megaprojects.

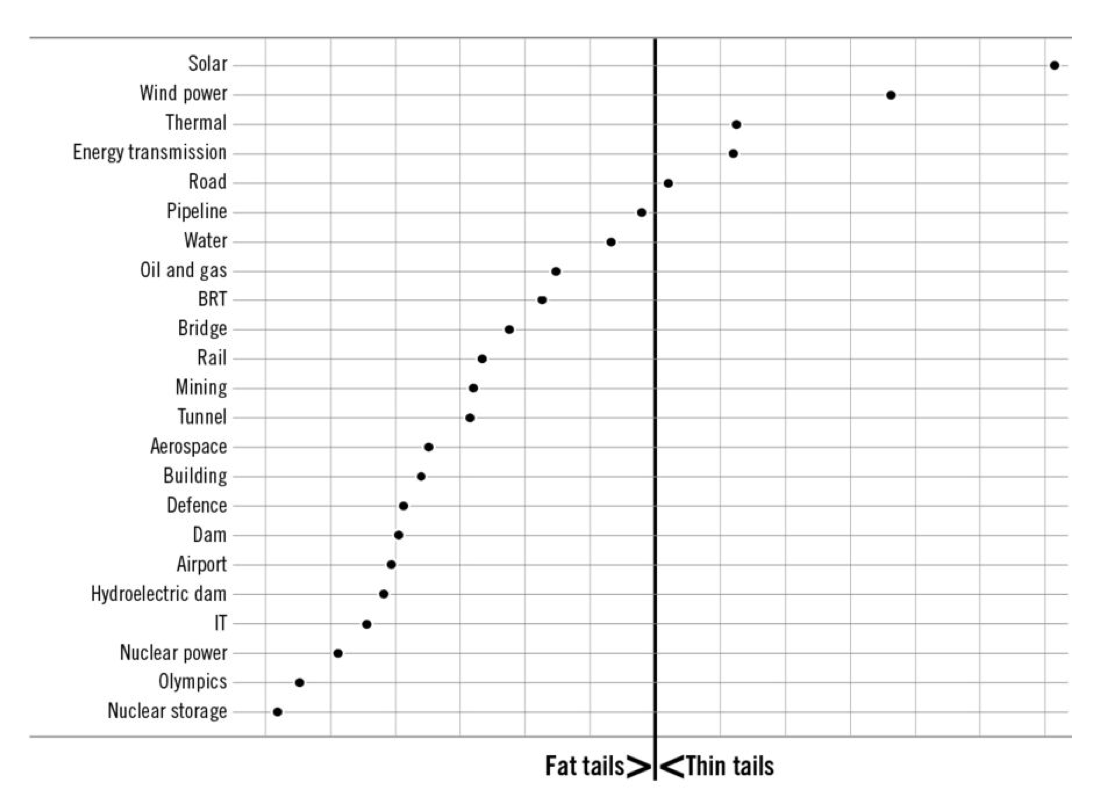

(The above is also from Professor Flyvbjerg’s research and shows an even worse situation than the previous graph. A “fat tailed” distribution means that when a project goes over, it is more likely to go way over; a “thin tail” means that overruns are clustered tightly around the average overrun. Fat tails mean that you can go three, four, five times past the average overrun; a thin tail means that you’ll very likely be close to the average. The worst case is a high average overrun and fat tail; the best case is a low average overrun and thin tail)

The megaproject types with the worst record were ones involving nuclear storage, nuclear power, airports, IT, and dams (and the Olympic Games, but we can treat that one as a special case). When these types of megaprojects run afoul of the Iron Law, their overspends and delays tended to be much bigger – they are “fat-tailed”.

STT is a pipeline, and therefore in the lower-risk bunch in both categories. SESRO has a 11-km-long wraparound dam and is squarely in the higher-risk category, both times – likely to go a long way over, and prone to going way over.

Getting round the Iron Law

It turns out that there are a bunch of rules you can use to get around the Iron Law. I’d love those who do discuss big infrastructure projects in the media and Parliament to be familiar with these. I’m going to discuss this in a bit of depth here, partly because I think it’s fascinating, and partly because it’s very useful to be aware of these if you’ve got any interest at all in national infrastructure.

If you’ve ever used Lego, you’ve probably got an instinctive grasp on the first rule already. Flyvbjerg found out that one common factor shared by most of the few megaprojects that avoided the Iron Law was whether you could build your megaproject out of repeatable modules. This was why projects like pipelines, solar farms, and wind farms could beat the Iron Law so often. He summarized it as saying that one of the most important things you could do was to “find your Lego”.

STT has “Lego”. Pipelines are made of repeatable bits. SESRO doesn’t.

Another rule was to plan, plan, plan before you ever start. Flyvbjerg, who has advised governments on this area (successfully), recommends that in situations where you can’t build small and iterate up, you create a “Maximum Virtual Product” before ever putting a shovel in the ground.

This means you create models both physically and in software at multiple scales, and as faithful as possible to what you will eventually build. Then you test these plans and models in depth, and iterate them until you have an exact model or digital twin of exactly what you’re going to build.

When you’ve got those first two rules down, you know exactly how you’re going to build whatever-it-is throughout the entire process; and you can get the bits you need to build it easily and repeatably, and work out who and what you need, when you need them, and where you need them.

Flyvbjerg calls it “Think Slow, Act Fast”. Changing your mind on a key aspect before spending millions digging huge holes all over the place is much more straightforward, cheaper, and easier. Moving things on a computer or a small model is a damn sight easier than filling in massive trenches, replacing roads, shifting bridges and tunnels, and moving dams around in real life. Then when you do build it, everything clicks into place quickly and easily, and you end up finishing it on schedule and on budget.

Most megaprojects do the reverse. They get approval on a high-level vision, and promptly start digging a hole large enough that no-one’s going to cancel their project without looking really dumb. It’s called “locking in the project” – that hole can only be filled by a lot of money. When it comes to megaprojects that go this route, always remember that “the initial estimate is just a downpayment”.

The few megaprojects that have beaten the Iron Law have all done the planning properly first. With the building of the Empire State Building, those working on it knew exactly where every brick was going before anyone arrived on site. Those building Heathrow Terminal Five knew the interrelationship between every aspect of a very complex megaproject – and who was needed, where they were needed, and when they were needed throughout. Contrast that with, say, the debacle of the building of Brandenburg Airport in Germany.

With SESRO, they haven’t even got a design yet. The idea is to lock in approval first and design it as they go. The design will be finished after construction has started. There will be no Maximum Virtual Product. Act First, Think Later?

There are more rules – Flyvbjerg talks about “establishing a reference class” (there is none for SESRO; STT has loads). “Hire a master builder” and “get the team right”, ensuring you have a lot of recent directly comparable expertise in the project leader and the team (again, none for SESRO, plenty for STT).

“Work out the goal – ask ‘why this way?’” Ensure you’re building the right thing – the NIC identified the right thing: a transfer grid.

“Watch your downside.” When certain types of megaprojects overrun, they really blow out the budget and schedule. Most megaprojects involving dams blow the schedule, and when they do, they go 200% or more over budget. Most of those involving pipelines come in on schedule, and those that go over, average only 14% over.

On almost every rule, SESRO fails. STT passes.

Planning the build

Thames Water still haven’t gone further than the preliminary design work in 2007, nearly 20 years ago (‘Upper Thames Major Resource Development: Draft Preliminary Design Report, v4.0’ 2.5.1 , Jacobs 2007). In that, the subcontractors had planned to do a 20m high test embankment. This was needed to work out the angles of the sides and the cross-section of the embankment – basically, the shape and size needed.

Thames Water have dropped that, instead having their 3 metre high Clay Compaction Trial. When asked, they tell us that they’ll tie in the test embankment with the construction itself. That is, they won’t do the test embankment until everything’s approved and they’re actually building it.

(This is the site of the Clay Compaction Trial, and all Thames Water propose to do before the go-ahead. As it happens, the bit under water wasn’t intended to be under water – the small clay bank is supposed to be constructed there – but they’re behind schedule as there was rain over winter)

This means they can’t have any good idea about the real cost of it until after they start building. It’s almost as if they’re reading Flyvbjerg’s book and saying, “I wonder what happens if we do the exact opposite?”

For some reason, I never see any pushback on Thames Water’s quoted timelines and budget; they tend to be swallowed whole and quoted without question. If it does go ahead, I fully expect them to be a case study in Flyvbjerg’s next book. The sad punchline being that this case study will be on all of our water bills for the next half-century. I don’t expect to see any water coming from it in my lifetime, even if they do manage to eventually complete it. But I’ll see much money going into it from my bills. And yours.

Disperse the risk, don’t concentrate it

If, after all consideration, we decide we do want more reservoir capacity, perhaps we should go smaller? There’s a sensible (or at least, less stupid) route that involves that. Instead of concentrating all eggs in one humongous basket, we disperse them into a bunch of smaller ones.

That is, we build multiple smaller reservoirs versus one mega-sized one. (I’m talking about the 30bn litre size, which is still equal to the largest bunded reservoir ever built in the UK.) Smaller ones can get built quicker, with less push-back and much less risk (both physically and project-wise). You start getting some benefits as soon as your first one is completed.

You’d not be so all in on a single huge mega-reservoir. If there’s difficulty in completing or even filling that huge single one, you’ve got nothing; with many smaller ones, you’ve got to be really unlucky to be in that position. Smaller ones won’t be strategic targets. They’ll involve much less disruption and impacts, and you’ll build up experience as you go.

You may think that building many smaller ones would give you more public resistance, but with them giving much less disruption (for less time) and covering less area, they can get through with fewer objections. I genuinely believe that a 30bn litres reservoir outside Abingdon would sail through approvals, like the Havant Thicket reservoir.

If you have a water network, you can even build these smaller reservoirs wherever you like – such as where it’s wet, where it’s hilly, and where there’s less call on the land in question.

That’s if you want reservoirs, anyway. There’s a real argument that desalination plants and water reuse are the only truly climate-change-resistant options; a water network works for these just as well.

Opportunity knocks never again

(The area of the megareservoir, photographed from above Drayton. It wouldn’t fit in that picture)

There’s yet another cost to any megaproject. Beyond the financial, beyond the resources of time and people, and beyond any cost to the environment or those around it. Economists call it “opportunity cost”. This essentially boils down to, “If you do this, you can’t do anything else with that money, time, people, or land.” (To which most of us would say, “well, duh,” but there’s a reason they call it the dismal science.)

The £2bn – £5bn, £10bn, £20bn, however much it ends up costing – won’t be available to be spent on anything else. It won’t be left in our pockets to help with the cost of living crisis; it won’t be spent on a Severn–Thames Transfer or any other infrastructure; it won’t be spent on housing or energy. The effort expended on SESRO won’t be available for STT or any other infrastructure, nor will the “political capital” expended.

The land will be consumed under it. All gone for good. It won’t be able to continue to be used for agriculture, nor for solar farms. (It currently holds several of these, including one that was the largest in England when constructed a decade ago.) Nor for wind turbines (it happens to be one of only eight sites in Oxfordshire suitable for a wind farm). Nor for housing (you could build a sizeable new garden village there, sustainably, and not in anyone’s backyard). Nor for a more realistic-sized reservoir, or for, well, anything else.

I’m not advocating any one of those here and now. But I’ve heard people seriously suggest each of them, and there are cases to be made for each of them. They all have costs and benefits to be considered, issues and questions, but none of these will ever be looked at if this goes ahead. SESRO kills the opportunities for any of those, whilst eating resources. Maybe we should make sure that SESRO is worth the corpses of those opportunities; that it is worth more than any of them.

The final summary

So – that’s where we are.

Let’s step past GARD’s (rather crucial!) question of whether more sensible abstraction targets, focusing on leakage reduction, using the right population projections is sufficient with the infrastructure already coming. Instead, we’ll assume that, for whatever reason, we’ve decided we do want to spend more on extra new water infrastructure.

- We know that the National Infrastructure Commission pushed for water transfers first and foremost.

- We know that a Severn–Thames Transfer would be the key east-west link in the potential national water grid. We can see that Thames Water don’t want it – for their own reasons.

- We know that SESRO would be unparalleled in size for its type, with equally huge issues and problems to resolve, including a very real possibility of risk to life and ongoing potential disruption.

- We know it would be very costly to start with, and near certain to see overruns in time and cost, and not just by a little, but by a lot.

- We know that the design isn’t anywhere near done, so those original estimates look like fiction right now.

- We know that despite the promises, there’s a real chance that we’d not see any recreational benefits after all, due to those issues it would have.

- We know that a much smaller reservoir (still equal in size to the largest of its type in the UK) wouldn’t have anything like those issues; we can reasonably suggest that it would be more likely to provide those recreational benefits; and it would be much easier to get approved, given the outcome of the 2010 public enquiry.

- We know that STT would be cheaper, more adaptable, quicker to build, less disruptive, more effective, and fit the bill of what was required by the NIC. It would also be easier to turn on and off, both in whether or not to build it or scale it up or down, or to operate when built. And it would make SESRO redundant immediately.

- We know that SESRO kills any other opportunities – for the funds, for the effort, and for the land.

- We know we lack expertise in building these kinds of reservoirs, and can conclude that building smaller ones first before deciding on something like this might be wiser.

- Beyond that, it looks likely that it would struggle to be filled sufficiently to be of use when we needed it, requiring ideal conditions before droughts. It looks a lot like the wrong reservoir in the wrong place, totally dependent on the most water-stressed major river on this island.

- There’s a possibility that we’ll end up with a huge hole in the ground and part-finished earthworks taking many years and many billions of pounds, whilst a couple of back-to-back droughts push politicians into emergency approval of the faster and easier STT to solve it rapidly. That would mean we’d end up with STT after all, plus a wasted and environmentally damaged area under a half-finished mega-reservoir. Which would lead to a difficult choice in a couple of decades: spend yet more billions of pounds and years of effort (and further damage) to complete, even though it may be unusable due to the difficulties and now redundant, or spend further billions to return to its original state.

I get why the water companies want solutions like SESRO – they don’t want to import from other water companies, and the commercial case is better for them. But no matter your feelings on whether water utilities should be privately owned, publicly owned, or not-for-profit public benefit companies, surely we can agree that they exist for us. Not us for them.

Thames Water keep telling people that SESRO is essential, and that we have no other options. And people keep printing that with minimal questions and challenge. But, as we’ve seen, we certainly do have options. (And if we’re truly looking at climate-change-proofing our water infrastructure, one of those should be the newer technology for desalination and/or water reuse.)

If you believe we need more water infrastructure to avoid the threatened “Jaws of Death” and aren’t convinced by GARD’s arguments, or you want extra resilience anyway, then why go the SESRO route? It’s the slowest, hardest, least effective, and most expensive option. Why choose to take the longer and slower route through these “jaws”?

And if, after all consideration, you decide that SESRO is the route forward, then why not require that Maximum Virtual Product to be planned out first? That concerns are answered upfront, without avoiding the answers until after approval and beginning work? It wouldn’t slow things down; they have to be answered anyway.

If we don’t answer the questions and address the concerns up front, they won’t go away. They can’t be shouted down. Reality will force the answers in time, and the later we address them, the more it will cost – in every sense.